A full-service custom packaging manufacturer in Denver, CO

The DeLine packaging legacy goes back over 100 years and, let’s face it, you get pretty good at things after a century of practice.

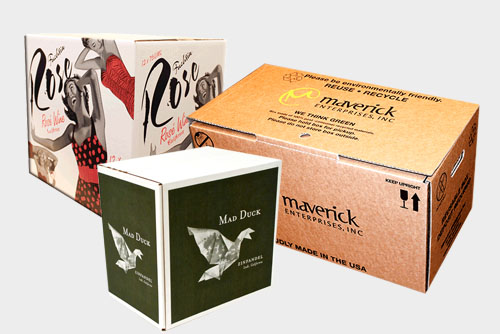

Make the most of retail marketing space. Our team turns your packaging into a revenue generator. Tell your story on the store shelves with brand building retail packaging.

Brewers of all sizes have utilized our print and design capabilities to make the most of valuable retail marketing opportunities. From trays, 6 pack carriers, 12 pack carriers to mother cartons we can help set your brand apart from competitors.

As e-commerce grows so does the need to have engaging packaging. We create e-commerce packaging that consumers look forward to receiving. Browse our gallery today.

Whether you are looking for product fulfillment, lead fulfillment or pick and pack, we can help.

PROUD SUPPLIERS OF

I finally took delivery of a bunch of boxes to kit up my first orders and wanted you to know that they turned out great. All the tolerances seem spot-on and the finished product is really nice. I, and the operations manager at my fulfillment center, were both very impressed with the absence of waste-material as well. The print quality is great, too. I’ve put together about 60 boxes so far and am averaging a 45 sec build time.

Its impressive how well a flat piece of cardboard transforms into a really elegant and simple container for our product. So, thanks for all of your help designing it and brining it to life.

Stay healthy!

Jeff Cornelius

Healthy Hydration for Kids